Enhanced performance across the entire supply chain

You would like to know more?

Contact us

Pharmacies face ever-growing challenges. The variety of products has increased, the way people shop has changed, and a huge volume of information is now instantly available everywhere – and much more besides. Even slight fluctuations in demand can create problems at the point of sale. Poorly coordinated processes and delays in the provision of information can lead to out-of-stock situations. If the product is not immediately available, customers simply go without, or switch to other brands or sales channels. The result is a loss of revenue and customer satisfaction. However, if distributors and pharmacies join forces to enhance and streamline their shared processes, it is possible to master a significant number of these challenges.

Is vendor managed inventory the answer?

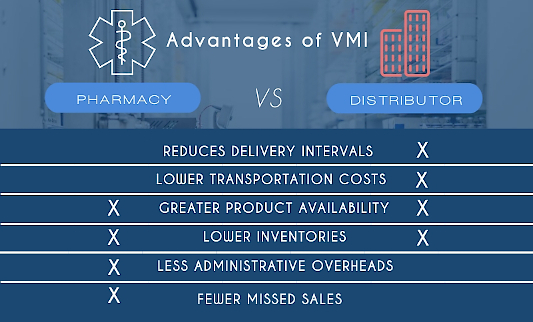

Logistical integration of pharmacies into the distributor’s supply chain opens up opportunities to minimize inventories, to cut the cost of the value chain and to enhance product availability – while eliminating duplication of effort.

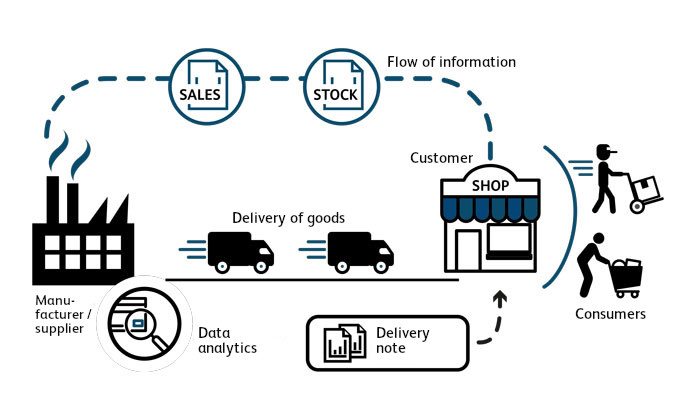

Vendor managed inventory (VMI) is when the distributor themselves controls and replenishes the stock of products held by the pharmacy. Responsibility for availability, for generating orders, and for timely replenishment therefore lies with the distributor. The pharmacy submits information – on current demand, inventory and forecasts – to the distributor electronically. With traditional vendor managed inventory, the goods, once delivered, become the property of the pharmacy. An alternative approach is consignment inventory. In this instance, the products remain the distributor’s property until they are taken from the pharmacy’s stockroom.

Automatically simpler

Dispensing and storage robots are an excellent way of streamlining the process. These solutions automatically capture data on the quantities of items put in storage and retrieved, and can therefore constantly monitor inventory. In this instance too, information is transmitted electronically to the distribution center. On-site inventory is managed using predefined maximum and minimum thresholds. When the lower limit is reached, the VMI process automatically generates an order within the distributor’s IT system. This is then fulfilled, and placed in the pharmacy’s VMI stock as usual.

Dispensing robots not only enable compact, efficient storage, their intelligent software also supports electronic data exchange, which is the prerequisite for VMI.

So what does this mean for the pharmacy? VMI helps them plan, reduces administrative overheads, helps prevent overstocking and understocking, and can cut costs. Particularly for pharmacies with automated storerooms, the process is an opportunity for greater business efficiency.

This article was written by Mario Ulrich. He is Global Sales Leader for Pharmaceutical Distribution Centers (PDCs) at BD Rowa. In this role, he represents BD Rowa with regard to potential and existing customers, partners and other market participants.

You might also be interested in

A positive team spirit for pharmacy success

A positive team spirit is an essential factor for the success of a pharmacy - and it can be achieved more easily with the proper support from technology.

What happens after you buy a robot?

Once the decision for a robot is taken, have a look at what will happen in your pharmacy as concrete next steps.

What is your biggest time waster in the pharmacy?

Time is often at a premium in pharmacies. But what takes up most of it? Pharmacy automation can help here.