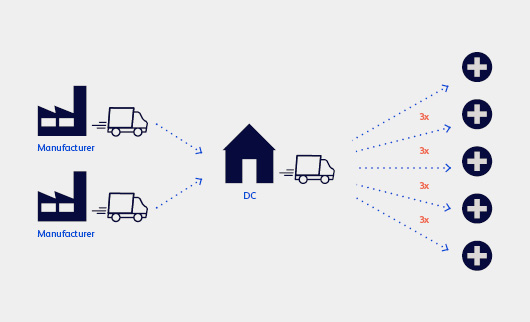

German pharmacies are supplied by wholesalers three times a day on average. This means that around 18,000 pharmacies in Germany receive approximately 4.6 million medicines per day from all wholesalers.1

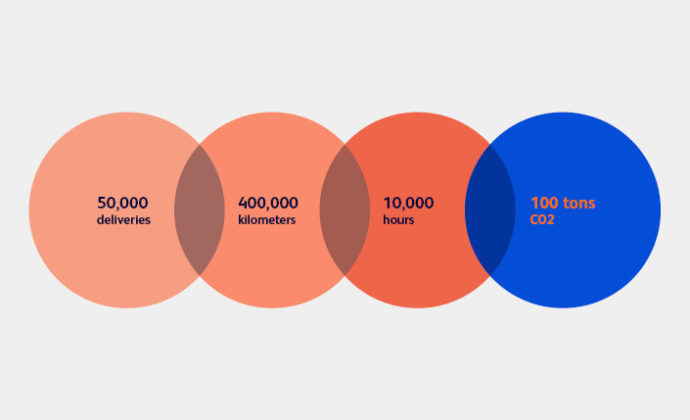

In this specific example, this high delivery frequency for just one full-line wholesaler generates around 100 tons of CO2 emissions and a daily burden on public roads of around 400,000 km. And that’s not all. Looking behind the scenes, specifically at the time planning, you will see that around 10,000 hours must be spent on daily transportation.

But why? If you ask the wholesalers themselves, one point is at the top of the list: This high level of delivery readiness is expected. Let’s change our perspective and ask why the high order frequency occurs in the first place. The reasons are manifold: despite having a pharmacy management system, the order quantities determined are often inaccurate, as the necessary parameter settings in the pharmacy management system often cannot be made sufficiently in daily practice. At the same time, attempts are made to reduce capital commitment by keeping stock levels low. Seasonal influences and fluctuations in demand also play a role.

Isn’t it the case that local pharmacies can only be successful if they can differentiate themselves from mail-order pharmacies and competitors through high product availability and exceptional, personalized service?

A possible solution from the pharmacy's perspective

If you are wondering how to achieve this during staff shortages, here is a possible solution: automated back-office processes. Sales processes are becoming increasingly digitalized, online and fully automated in the pharmacy’s back office, which in turn requires a more extensive stock of medicines in the pharmacy to meet customer demand. Patients who order online tomorrow will probably order where the medicine is in stock.

So, if we assume that high product availability is a prerequisite for sales growth in the pharmacy, it must be ensured that the stock meets demand 24/7. Are you a pharmacy owner with more than one pharmacy? Have you ever thought about bundling your back-office processes? Managing orders more efficiently, economically and sustainably can make perfect sense.

For a sustainable supply of medicines, wholesalers would also have to adapt the delivery routes to the pharmacy.

The supply chain from the perspective of pharmaceutical wholesalers

Pharmacies want to be supplied by their wholesaler several times a day. This presents them with several challenges that are not always aligned with efficiency and sustainability.

Many large cities are already off-limits for vehicles, whether diesel or electric. New ideas are needed to continue to deliver medicines to pharmacies economically and sustainably. Switching to electric cars alone will probably not be enough.

Sustainable and high delivery reliability: a contradiction?

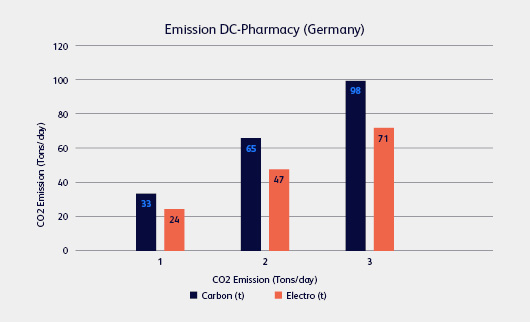

Route optimization based on current supply chains could reduce CO2 emissions. Switching from fuel-powered to electric vehicles is an important issue, but currently only reduces CO2 emissions by 24% ³ and is costly and time-consuming. A more significant and faster effect can be achieved by lowering daily mileage by up to 67%**.

**Mathematical calculation (see below)

The magic word "supply chain optimization" - fewer kilometers with the same delivery readiness?

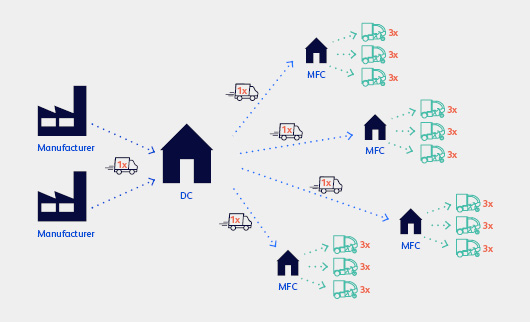

Retailers began setting up small logistics hubs (MFCs) in larger cities many years ago. This allows orders to reach customers faster and more cost-effectively. The hubs are centrally located and, therefore, close to customers – this enables same-day delivery, among other things.

In an MFC of just 300m2, orders for up to 25 pharmacies could be picked daily, consolidated by district and delivered to households in a route-optimized manner over the last mile, e.g. using eCargo bikes. The wholesalers can handle the transport logistics or outsource to a city logistics company. Taking Germany as an example, around 6,400 pharmacies (approx. 35%) in cities with more than 100,000 inhabitants could be supplied by MFC. The advantages are obvious: short delivery times, lower delivery costs, reduced CO2 emissions and, above all, free access to inner-city pharmacies – we remember the “car-free inner cities” scenario above.

How could deliveries be organized in the future?

Based on the following information, we can say that by introducing micro fulfillment centers and last-mile logistics in the traditional supply chain, wholesalers could achieve significantly lower mileage with the same or even higher delivery readiness to pharmacies as follows:

1: If MFCs were set up in cities with more than 100,000 inhabitants, each MFC could supply up to 25 pharmacies on average.

2: Wholesalers supply all other urban and rural pharmacies only once daily with a primary delivery (without MFCs). Supply bottlenecks are not expected, as stocks could be continuously optimized seasonally in cooperation between wholesalers and pharmacies.

3: Reorders on the following day by pharmacies in large cities will, in the future, be picked up by MFC and delivered to pharmacies by eCargo Bikes.

This results in the following supply chain between wholesalers and pharmacies and, overall, a considerable reduction in CO2 emissions, driver hours, road congestion and shorter delivery times:

About the author

Mario Ulrich, Global Business Development Leader Pharmaceutical Distribution Center

1 https://www.phagro.de/wirlieferngesundheit/

² Own calculation based on information from the Federal Environment Agency, Phoenix and assumptions.

³ Federal Environment Agency: Further development and in-depth analysis of the environmental balance of electric vehicles